- +91 97919 00767

- libertymatch@gmail.com

About Us

Who We Are

Have a look at our progress!

Liberty Match Company (P) Ltd., was founded by the illustrious ‘SSD’ family, about four decades back. The untiring efforts of the promoters have resulted in the marvelous development of the company, with 12 match manufacturing units, a highly sophisticated printing complex with all allied facilities, and a splint manufacturing unit works by the way of backward integration. All the units put together offer employment to more than 1600 employees, producing 5 million match boxes per day to cater to the requirements of our widespread market at home and abroad.

A fireworks manufacturing factory has been set up by a way of product diversification. Besides, Liberty is also engaged in dealing with match manufacturing machinery along with technology transfer to developing countries.

Thanks for your dedication! The matches manufactured by your team is exceptionally superb.

Rash MI

The quality of the matches you deliver is great and it can be used for various purpose.

S. Santhosh Kumar

Very delighted to purchase matches from your team, your assistance is great.

K. Kumar

Our Process

The works that speak our reputation!

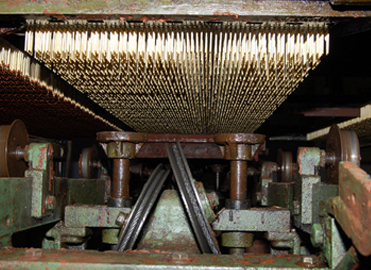

Splints Insertion

The insertion of match splints is carried out by a system of combs and grooved plates. The splints are inserted into the perforated bars called splint bars and it comprises a plate mat that serves as the carrier of the splints in the processes of waxing, dipping, and drying.

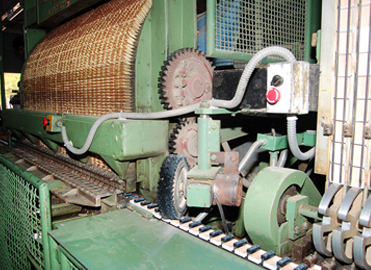

Paraffining

Splints are preheated and dipped in the molten paraffin wax.

Dipping

After paraffining, splints are carried by the splint bars to the dipping device where the head composition of the match stick is applied. The splints are dipped in a composition container which is a round tray. The dipping tray is steam heated to keep the composition at a favorable temperature.

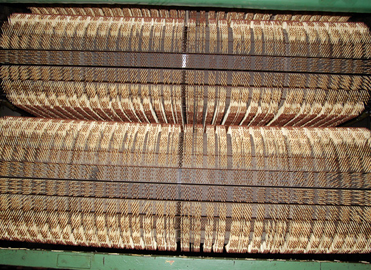

Drying

After dipping, the splints carried by the splint bars will travel in horizontal loops through the drying unit, which dries the match head by fanning hot air from the steam heated radiators..

Innber Box Making & Conveying To Filler Head

Inner boxes made from the cardboard slit reel in High-speed Inner Box Making Machine and the boxes are blown with Air Blower to the overhead bunker.

Box Filling

The Inner boxes fed to Filler Head are passing through the Dipping machine Splints Discharging Unit and during discharging, splints are directly collected into the inner box according to the counts settled.

Outer Boxes

Outer boxes are made in high-speed outer box machine and it passes through Single conveyor to Snake Bar. The Snake bar distributes the outer boxes to the Belt Conveyor evenly, and Boxes reach the Filler Head.

Box Closing

In the Filler Head, the Inner box with Splints and Outer box are semi-closed in the first step. Then semi-closed boxes will pass through an Inspection Table. The counts are checked in Inspection Table.

Tray Collection

The completely closed boxes are arranged in Tray by Tray arranging Unit

10’s Packing

The boxes collected in the trays are feed to 10’s packing machine and packed into 10 Matchboxes.

100’s Packing

10 boxes collected from 10’s packing and packed into 10 boxes. It contains 100 (10X10) Matchboxes.

Cartons Packing

10 boxes collected from 100’s packing and packed into 10 boxes. It contains 1000 (10 X 10 X 10) Matchboxes.